Brand of DEKCEL, CNC router, CNC laser, CNC parts manufacturers and suppliers in china. Supply different types of cnc routers machine used in different industries.

What is A CNC Router?

The CNC router is an intelligent CNC ( computer numerical control ) processing equipment. In terms of processing principle, it combines engraving, cutting, drilling, and milling. An automatic CNC router machine consists of a CNC operation system, processing software, spindle, transmission system, and vacuum working table.

Working Principle of CNC Router

A CNC router machine is controlled by a G-code based on its instruction code and its operating system to set the processing route, processing parameters, tool motion path, cutting parameters (spindle rotation, RPM, feed, return, etc.), and the auxiliary functions of the parts ( tool replacement, forward spindle rotation, reverse rotation, opening cutting fluid, etc.). A variety of processing programs are used to accomplish the purpose of automatic processing.

How Many Types of CNC Routers?

Customers will choose the most suitable CNC router model according to their business needs and budget. Generally, our CNC router table sizes mainly include 2x2, 2x3, 2x4, 4x4, 4x6, 4x8, 5x10 and 6x12 in feet, someone may call the table sizes as 4040, 6040, 6060, 6090, 1212, 1218, 1224, 1325, 1530, 2030 and 2040 in millimeter (mm).

To meet the processing requirements of different materials and industries, we also have other types of CNC routers, such as Wood CNC Routers, Hobby CNC Routers, Advertising CNC Routers, Metal Engraving CNC Routers, Stone Engraving CNC Routers, 3D Engraving CNC Routers, Nesting CNC Routers, ATC CNC Routers, 4 Axis CNC Routers, 5 Axis CNC Routers and other kinds of customized CNC router machines.

How To Choose A CNC Router Machines?

1. Table Size

According to the customer's business and processing materials size, choose the table size and type. In the market, the main size for the wood board, PVC board, acrylic board, and MDF board is 1220mmx1220mm, 1220mmx2440mm, 2000*2800mm, 2000*4000mm or other customized special sizes.

Our standard affordable CNC router equipment includes DEK-1212M, DEK-1325M, DEK-1530M, DEK-2030M, and DEK-2040M and can be customized the router machine size according to the customer's request.

2. Spindle Motor

The spindle is one of the important parts of the CNC engraving machine. Choose the famous brand for your CNC router machine, like Chines Hanqi / Changsheng / HQD, Italy HSD.

Selecting the suitable router spindle according to the processing material will greatly improve production efficiency and save costs, regarding the spindle motor of a CNC router machine, the higher power, the better.

A lower power spindle is mainly used for the advertising industry and small parts fine milling and engraving. With the characteristics of high power and stronger processing ability, the high-power spindle woodworking CNC router is mainly for cutting, engraving, drilling, milling, carving, grooving, relieving solid wood, hardwood, plywood, MDF, stone, foam, ceramic, plastic, acrylic, glass, PVC, PCB, ACM, brass, aluminum, copper and other kinds of materials.

3. Machine Body

An important part of a woodworking CNC router machine is its body which allows it to have a stable and good performance. Therefore, long-term high-power machining should choose the heavy-duty, high precision, or casting body to ensure its processing accuracy and stability.

4. Transmission System

Generally, there are two main driven systems for CNC router machines: ball screw and rack guide rail transmission. So, choosing a suitable router machine configuration can improve processing accuracy and production efficiency, and the service life of woodworking engraving machine equipment.

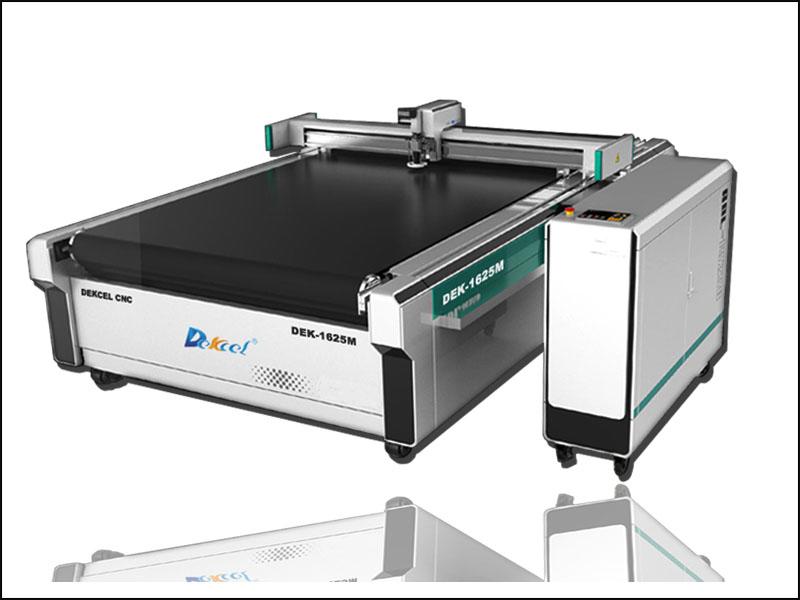

The best CNC router manufacturer in China, DEKCEL CNC offers high-performance, affordable, and cost-effective CNC wood routers, metal and nonmetal laser cutting machines, CNC plasma cutting machines, and CNC knife cutter machines.

CNC routers are ideally suited for residential and commercial woodworking, fabricating plastics and composites, shaping and inlaying solid surfaces, machining non-ferrous metals, and more. Offer a wide range of CNC engraving machines, including stone engraving machines, 3-axis CNC routers, 4-axis CNC routers, 5 axis CNC routers, which can be processed wood, plastic, non-ferrous metal, etc. Whether you are looking to purchase your first CNC router machine to start in the engraving and cutting industry or add a second router CNC to your line, it is tailored to give you an affordable CNC router that meets your exact demand and budget since it is with over 100 configurations and ODM accept also.

Strives to provide the best of what's most important to our users – engraving and cutting quality, speed, reliability, and ease of use. By utilizing only the highest-quality components, affordable CNC routers are known worldwide for their reliability and performance, which translates into less downtime and more profits.

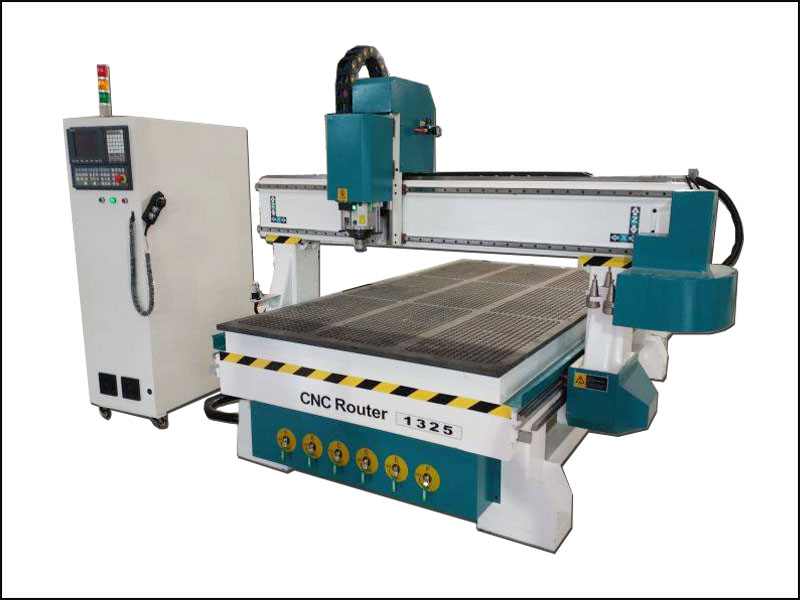

Cnc wood router carving machine for sale

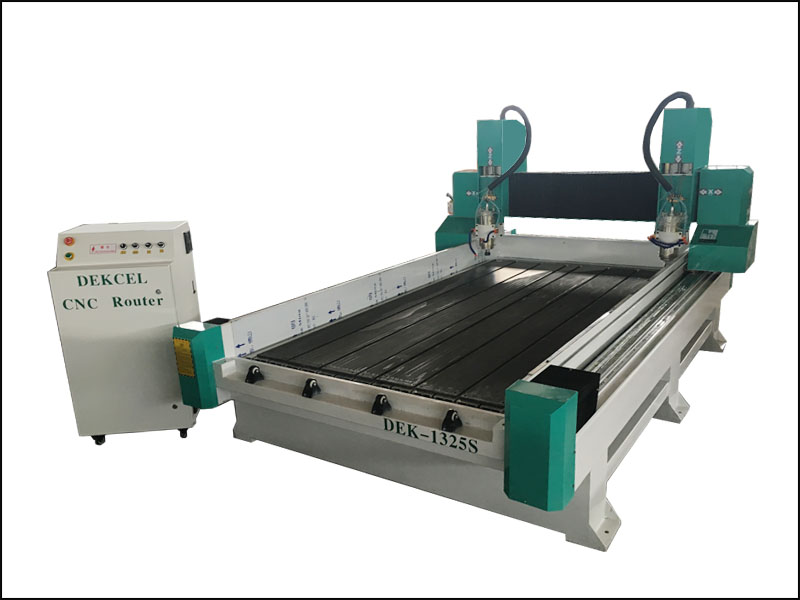

Cnc wood router carving machine for sale  Double processing wood router engraving machine

Double processing wood router engraving machine  Furniture Cnc router woodworking engraving machine

Furniture Cnc router woodworking engraving machine  China best price wood cnc router

China best price wood cnc router  Three spindle wood furniture cnc router machine 1325

Three spindle wood furniture cnc router machine 1325  Best cnc wood cutting router machine

Best cnc wood cutting router machine  Wood cabinet furniture side hole drilling cnc router machine

Wood cabinet furniture side hole drilling cnc router machine  China 2030 Wood Acrylic Board Engraving CNC Cutter Router Machine

China 2030 Wood Acrylic Board Engraving CNC Cutter Router Machine  Liner automatic tool change atc cnc router

Liner automatic tool change atc cnc router  ATC 4x8 cnc router woodworking machine

ATC 4x8 cnc router woodworking machine  China cabinet ATC woodworking cnc router with auto load unload system

China cabinet ATC woodworking cnc router with auto load unload system  Richauto DSP 0609 ATC Metal Copper Mold Milling Carving Laser Cutting Router Machine

Richauto DSP 0609 ATC Metal Copper Mold Milling Carving Laser Cutting Router Machine  DSP Linear ATC woodworking Cutting Drilling CNC Router

DSP Linear ATC woodworking Cutting Drilling CNC Router  Economic ATC cnc router for wooden door and furniture

Economic ATC cnc router for wooden door and furniture  China ATC Cnc wood carving machine for sale

China ATC Cnc wood carving machine for sale  Customized furniture production linear ATC wood MDF cnc engraving router machine

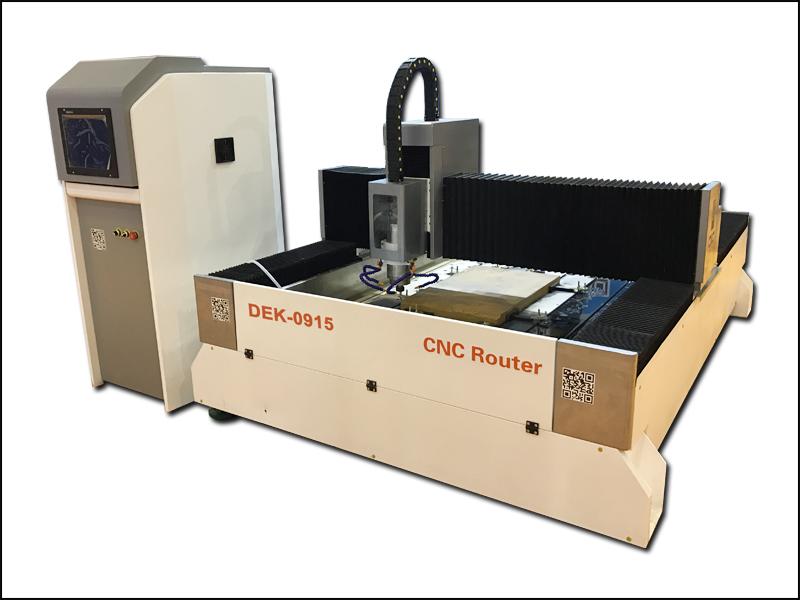

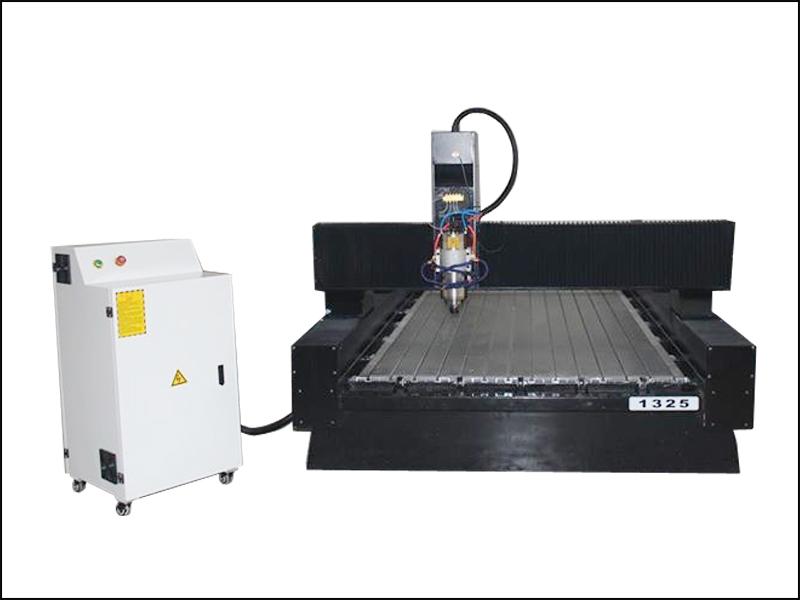

Customized furniture production linear ATC wood MDF cnc engraving router machine  3D Stone Carving Machine For Sale | CNC Router Stone Engraving Machine Price

3D Stone Carving Machine For Sale | CNC Router Stone Engraving Machine Price  7.5KW Water Cooling Spindle Servo Motor Granite Stone Engraving and Carving Router Machine

7.5KW Water Cooling Spindle Servo Motor Granite Stone Engraving and Carving Router Machine  Dekcel CNC® 3D letter carving on marble granite tombstone cylinder rotary cnc router machine

Dekcel CNC® 3D letter carving on marble granite tombstone cylinder rotary cnc router machine  China stone engraving cnc router machine manufacturer

China stone engraving cnc router machine manufacturer  Granite stone engraving machine for sale

Granite stone engraving machine for sale  Stong and marble cnc router carving machine

Stong and marble cnc router carving machine  Copper metal engraving laser cutting machine for sale

Copper metal engraving laser cutting machine for sale  6060 DSP 3D aluminium mould milling cnc router machine

6060 DSP 3D aluminium mould milling cnc router machine  4040 Mini DSP Mini Metal Mold Engraving Milling CNC Router

4040 Mini DSP Mini Metal Mold Engraving Milling CNC Router  Dekcel CNC ® 0609 metal 3D mould engraving and milling cnc router machine

Dekcel CNC ® 0609 metal 3D mould engraving and milling cnc router machine  Metal engraving cnc router machine

Metal engraving cnc router machine  Aluminum steel metal molding engraving machine

Aluminum steel metal molding engraving machine  Best 4 Axis CNC Router Tool Changer | ATC Woodworking Machine For Sale

Best 4 Axis CNC Router Tool Changer | ATC Woodworking Machine For Sale  4 Axis Wood Mould Carving and Engraving ATC CNC Router Machine Price

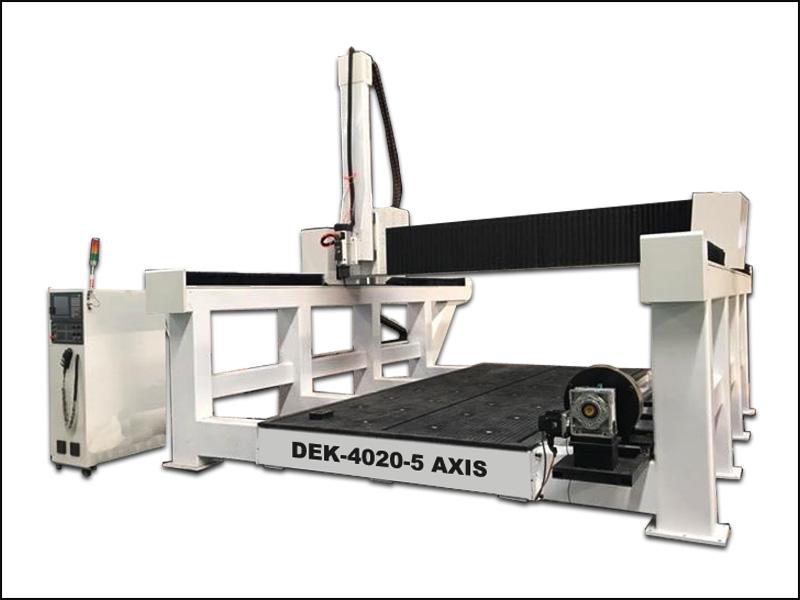

4 Axis Wood Mould Carving and Engraving ATC CNC Router Machine Price  3D wood sculpture cnc router carving machine 5 Axis

3D wood sculpture cnc router carving machine 5 Axis  Mini 5 axis aluminium metal mold milling engraving router machine

Mini 5 axis aluminium metal mold milling engraving router machine  Foam cnc engraving & router machine 4 axis

Foam cnc engraving & router machine 4 axis  Cnc wood engraving machine 5 axis for sale

Cnc wood engraving machine 5 axis for sale  Dekcel cnc router 4 axis manufacturer 1325

Dekcel cnc router 4 axis manufacturer 1325  Best Cabinet Door CNC Router Bits | Furniture Making Machine For Sale

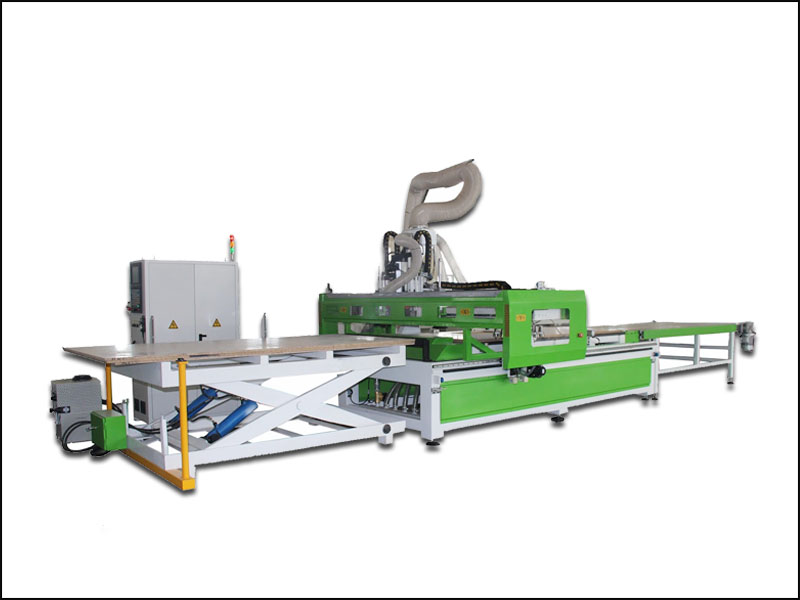

Best Cabinet Door CNC Router Bits | Furniture Making Machine For Sale  Customized Wooden Furniture Processing Cutting CNC Router Machine Center

Customized Wooden Furniture Processing Cutting CNC Router Machine Center  Double worktable 4 process furniture woodworking engraving drilling cnc router

Double worktable 4 process furniture woodworking engraving drilling cnc router  HSD 5+4 Boring Spindle ATC Wood Furniture Cutting Drilling Engraving CNC Router

HSD 5+4 Boring Spindle ATC Wood Furniture Cutting Drilling Engraving CNC Router  ATC Wood Plate Customized Furniture Production Line Cutting Drilling Router

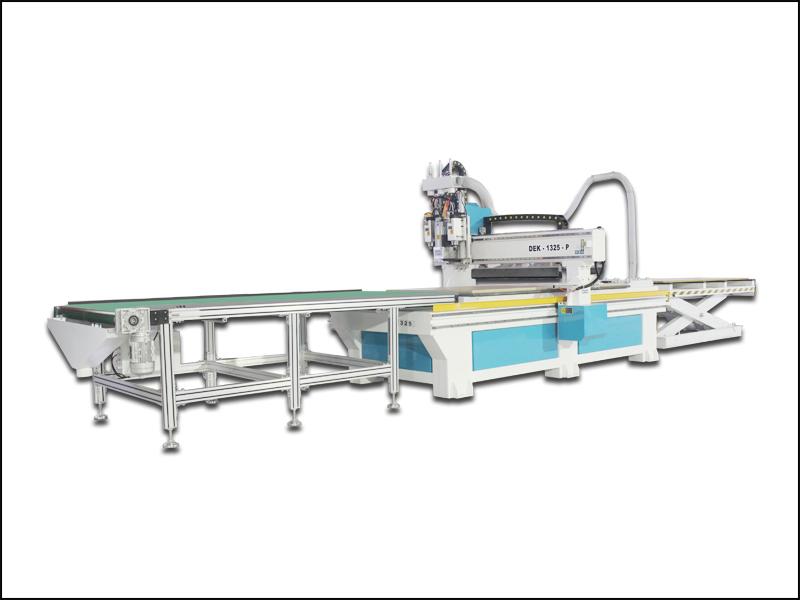

ATC Wood Plate Customized Furniture Production Line Cutting Drilling Router  Automatic wood carving machine furniture production line

Automatic wood carving machine furniture production line  DIY Film Plotter Cutter | Mobile Phone Screen Protector Film Cutting Machine

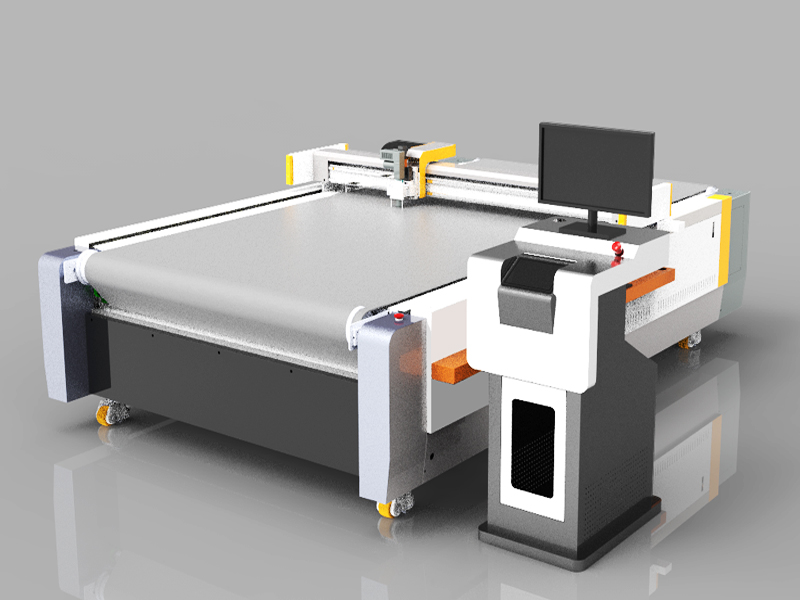

DIY Film Plotter Cutter | Mobile Phone Screen Protector Film Cutting Machine  Ceramic Catalytic Converter Exhaust Flange Gasket Cutting Machine

Ceramic Catalytic Converter Exhaust Flange Gasket Cutting Machine  Prepreg Cutting Machine | Composite Carbon Fiberglass Cutter Price

Prepreg Cutting Machine | Composite Carbon Fiberglass Cutter Price  Package Box Cutting Machine | Bags Sample Oscillation Knife Plotter Cutter Machine

Package Box Cutting Machine | Bags Sample Oscillation Knife Plotter Cutter Machine  Ceramic Fiber Expansion Gasket Cutting Machine | Insulate Foam Mat Oscillating Knife Cutter Plotter

Ceramic Fiber Expansion Gasket Cutting Machine | Insulate Foam Mat Oscillating Knife Cutter Plotter  Digital CNC Cardboard Cutting Machine | Corrugated Sheet Knife Cutter Price

Digital CNC Cardboard Cutting Machine | Corrugated Sheet Knife Cutter Price  Polyester Fiberglass Insulation Board Cutter | Sound Absorbing Panel Knife Cutting Machine

Polyester Fiberglass Insulation Board Cutter | Sound Absorbing Panel Knife Cutting Machine  Vinyl Leather Cutting Machine | Fabric Punching Pen Drawing Knife Plotter Cutter Machine

Vinyl Leather Cutting Machine | Fabric Punching Pen Drawing Knife Plotter Cutter Machine Home | About Us | Application | Industry News | FAQ | Cnc Hot Products