Brand of DEKCEL, CNC router, CNC laser, CNC parts manufacturers and suppliers in china. Supply different types of cnc routers machine used in different industries.

Metal laser cutting is a fabrication process that use laser to cut and remove the unwanted parts from a whole metal sheet. The metal laser cutter works by a high density light beam to create designs and patterns by physically removing or cutting the material. With the features of high precision, accuracy, fast cutting speed and perfect cutting effect, the metal laser cutter highlights its advantages in metal processing industry. With the continuous development and improvement of laser technology, laser power and cutting capacity have gradually increased, and metal laser cutting machines have become the mainstream equipment on the market.

Metal laser cutter is a type of laser cutting equipment specially used to cut and process metal materials. At present, the affordable laser metal cutting machines on the market mainly include CO2 300w laser cutting machine and fiber metal laser cutting machines. Due to its cutting power and capacity, the fiber metal laser cutting machine is the the mainstream metal laser cutting equipment in the market, with the advantages of strong cutting ability, high cutting precision, wide processing range and the fiber metal laser cutter is widely used in various industries.

1. The laser is emitted from the laser generator and then concentrated into a small spot by an optical focusing lens to obtain a high density power at the focal point of the laser beam.

2. Due to the continuous output of the laser, the heat of the laser beam (i.e. converted by light energy) at the focus point rises rapidly and reaches the vaporization temperature instantaneously, causing evaporation and forming holes in the metal material.

3. Setting well the parameters in the software of metal laser cutting machines, with the relatively linear movement of the beam and the material, the hole continuously forms a 0.1mm narrow width slit.

4. An auxiliary gas should be used during the cutting process to blow away the slag in the slit and to cool the focusing lens and protective lenses.

5.With the fast metal laser cutting speed and auxiliary gas, the thermal influence of trimming is very small, and there is basically no deformation of the workpiece.

1. Stable Performance

The metal laser cutter adopts gantry structure, high strength welding frame,stress reduction treatment, good rigidity, small deformation.

2. Fast Cutting Speed

Our CNC metal laser cutting machine equipped with precision servo motor and high accuracy transmission system,the metal cutting speed can up to 240m/min.

3 High accuracy

Fine laser beam quality of new generation laser source, the metal cutting machine accuracy is within 0.03 ~ 0.05mm.

4. Perfect Cutting effect

Fine laser beam, small laser spot and high energy density offer the sheet metal laser cutter can obtain better cutting quality.

5. Non-contact cutting

No contact with sheet metal during laser cutting,fast cutting speed and there is no deformation of the sheet metal.

6. Save Cost

Easy for operation, less consumption and running cost, can effectively reduce the laser metal cutting machine costs.

If you are working in the metal processing industry and want to find a laser cutter for metal, here are listed 6 steps to help you choose the right metal laser cutters:

1. Sheet Metal Cutting Size

According to your sheet maximum cutting size to choose the suitable laser machine, the standard model are DEK-1390FC, DEK-1325FC, DEK-1530FC, DEK-2040FC, DEK-2060FC or customized for you.

2. Metal Laser Cutting Power

Different metal cutting thickness will select different laser power. At present, the laser power in the market mainly have 1000w, 1500w, 2000w, 3000w, 4000w, 6000w, 8000w, 12000w, 20000w, 40000w.

3. Purchase Budget

As we all known, the higher laser power, the faster cutting speed and capacity, and consequently the purchase cost will increase also.

4. Self-Analysis & Evaluation

The following factors need to be considered when buying a metal laser cutter machine, such as types of metal materials, max cutting thickness, business scope and company production valve ect.

5. Machine model selection

Different types of materials need different metal laser cutting machines, there are 6 models laser metal cutters for you listed as below:

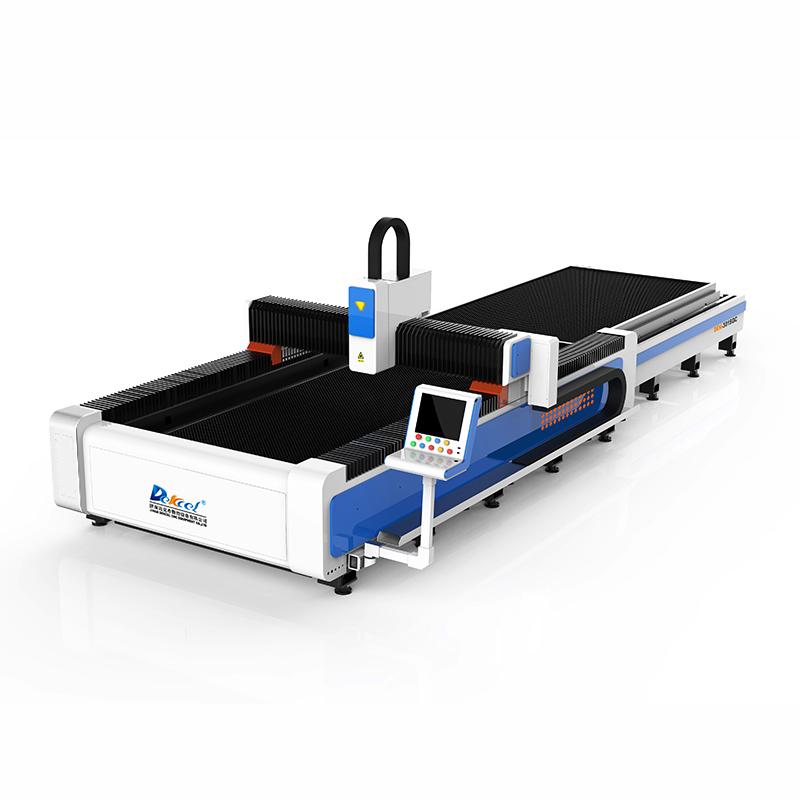

- Sheet metal laser cutters.

- Automatic laser tube cutters.

- Dual-purpose laser cutters for sheet metals and metal tubes.

- Automatic exchange platform metal laser cutting machine.

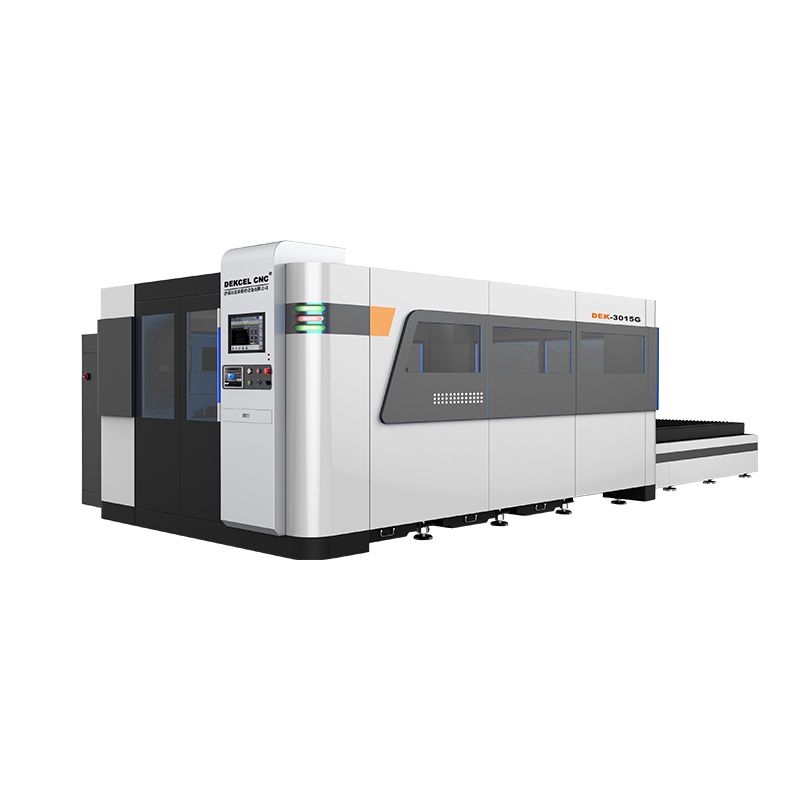

- Safety protection cover fiber metal cutting machine.

- 3D robot metal laser cutter machines.

6. After-sale-service

High quality metal laser cutter with good after-sales service and professional technical support, guarantee the high productivity of metal sheet laser cutter machines and improve the processing efficiency.

Application Materials

Stainless Steel Sheet, Mild Steel Plate,Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Applications Industry

Sheet metal fabrication, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, food machinery, textile machinery, engineering machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool machining, decoration, advertising , Metal external machining, kitchenware processing and other industrial manufacturing industries.

20000W CNC Metal Fiber Laser Cutting Machine Price

20000W CNC Metal Fiber Laser Cutting Machine Price  China Raycus 12000w Fiber Metal Laser Cutter Machine for Sale

China Raycus 12000w Fiber Metal Laser Cutter Machine for Sale  High precision stainless steel carbon steel fiber laser cutting machine

High precision stainless steel carbon steel fiber laser cutting machine  Fiber Laser Metal Sheet And Tube pipe Cutting Machine for sale with good price

Fiber Laser Metal Sheet And Tube pipe Cutting Machine for sale with good price  DEK-1325LC Metal fiber sheet laser cutting machine with Co2 non-metal cutting for sale

DEK-1325LC Metal fiber sheet laser cutting machine with Co2 non-metal cutting for sale  Low price 500W 1000W fiber laser cutting machine for sale

Low price 500W 1000W fiber laser cutting machine for sale  Affordable Stainless Steel Metal Fiber Laser Cutter Machine

Affordable Stainless Steel Metal Fiber Laser Cutter Machine Home | About Us | Application | Industry News | FAQ | Cnc Hot Products