Brand of DEKCEL, CNC router, CNC laser, CNC parts manufacturers and suppliers in china. Supply different types of cnc routers machine used in different industries.

Views: 896 Author: Site Editor Publish Time: 2021-06-24 Origin: Site

The CNC knife cutting machines (i.e., knife cutter plotter) is intelligent digital equipment that processes the materials by the high-frequency vibration or rotation of the knife blade.

Compared with laser cutting technology, there is no burn or smoke during the processing, which is totally environmental protection and good for worker's health.

A wide range of cutting tools are offered to process different kinds of materials, such as EOT, POT, V-cutter, Creasing Wheel, Hole Punching, Driven rotary Tool, universal cutting tool, and Kiss-cut CCD camera, Projector, Auto feeding conveyor, Spindle, etc.

The multi-functional tools and knife cutting solutions can be offered and customized for the complex processing of some unique materials.

Different industries have different names. And the CNC knife cutting machine also called an oscillating knife cutting machine, oscillating cutter plotter, CNC knife cutter, oscillating knife cutter, digital knife cutter, flatbed cutter, cutter plotter, CNC knife cutter plotter, flatbed cutter plotter, CNC digital knife cutting machine, knife cutting system, flatbed knife cutting table, CNC knife cutting table, and so on.

Digital cardboard plotter cutter equipped with full cut, kiss cut, creasing wheel, v-c ut, laser red light positioning functions, HD CCD positioning and camera extract large contour to cut. This digital knife cutting plotter is widely used in packaging and signs, including paper, board, sticker, vinyl, etc.

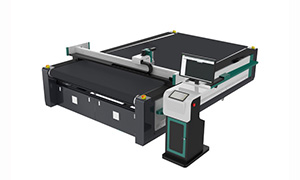

Flatbed knife cutter plotter machine is our standard model. We mainly use it to process leather, fabric, foam, PVC, rubber, and other flexible materials. More cutting tools are offered for your option equipped with EOT ( electric oscillating tool ), driven tool, round tool, POT ( pneumatic oscillating tool ), creasing wheel, v-cut, kiss cut, mark pen, etc.

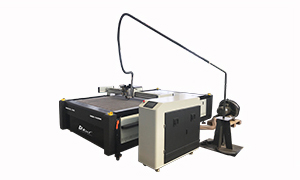

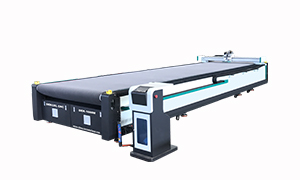

Automatic conveyor system CNC oscillating knife cutting machine is mainly used to process soft and flexible materials such as fabric, leather, textile, carbon fiber, fiberglass, rubber, etc.

CCD camera knife cutting plotter machine with large format visual recognition contour cutting. This function is for cutting printed pattern materials like fabric, cloth, foam, leather precisely cut, such as for digital printing board, KT board, PVC board, patterned mat, and various graphics printed on garment fabric, garment, cloth, etc.

Digital projection oscillation knife cutting plotter machine with visual camera system is especially for the shoe production industry, you can manually or auto nesting the parts on the material by the projector, then the EOT tool will cut the parts follow the part's contour.

This multi-functional flatbed cutter plotter can be equipped with an electric oscillating tool, creasing wheel, v-cutter, CCD camera, Italy 1100w router spindle. Except for cutting soft and flexible materials, this model with a router spindle can also process hard materials such as aluminum, wood, PVC, acrylic, MDF board, plastic sheet, and other composite materials.

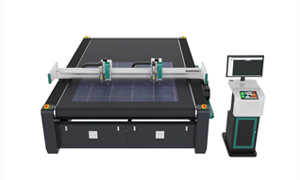

This flatbed knife cutter plotter with two head and cutting tools, these two sets of knife cutting tool work simultaneously and cut the same pattern, highly improve the production efficiency and save cost.

This model has two gantries and two cutting heads. Each cutter head works independently and does not interfere with the other. These two tools can process different patterns simultaneously.

This digital knife cutting machine with six projectors and an automatic feeding system is mainly used for cutting striped fabric and plaid patter garment materials.

In order to meet the processing requirements of different customers, we can customize the machine size, processing tools, and cutting solutions.

There are many types of digital Knife cutting plotter systems for processing a variety of materials. For more oscillating knife cutting machines, please visit our catalog of digital knife cutter plotter machines .

China Kinco Control System

• LED touch screen

• Digital operation panel

• Humanized operation interface

• Easy operation and powerful.

German igus Cables & Chain

• Flexible and long-lasting

• Shielded protection wires

• Flame retardant

• Silicon free

• Oil resistance

Multi-functional Tools Holder

• Multiple tools selection

• EOT / POT tool

• Creasing Wheel

• V-cutter, CCD camera

• Auto-feeding belt

• Router Spindle

Generation Aviation Aluminium Gantry

• Light weight

• Aging treatment

• No deformation

• Anti-oxidation

• Corrosion resistance

• High processing accuracy

Heavy Duty Machine Body

• Steel tube weld body

• Totally weight is 1450KGS

• Annealed and heat treated

• High strength and stability

• Tensile strength

• Long service time

8 Zones Vacuum Table

• 8 independent vacuum zones

• Strength adsorption capacity

• Each zone can be controlled

• Powerful adsorption effect for small size materials

German Innowelle GmbH Motor Reducer

• Excellent positioning accuracy

• Zero backlash

• High torque capacity

• Lifelong precision

• High single stage gear ratio

• Compact and lightweight

Japan Panasonic Servo Motor

• High ratio of torque to inertia

• High response

• High-precision positioning

• Fast cutting speed

• High processing accuracy

Taiwan PMI / HIWIN Guide Rail

• Higher loading capacity

• High rigidity

• Long service life

• High speed and accuracy

• High repeated positioning precision

France Schneider Electric Components

• Circuit breakers

• Power switchers

• DC Power supply

• Relays

• E-stop switch

Taiwan Airtac Solenoid Value

• Air control circuit system

• Sensitive reaction

• Good tightness

• Stability and long life

Japan Omron Photoelectric Sensors

• High repeat positioning accuracy

• Good reliability

• Long service time

• Guarantee machine accuracy

Different industries with different materials and processing technology, so that the selection of the cutting tool will be various also for our digital knife cutting machine. In order to meet the processing requirements for different materials, we can equip a multi-function CNC knife cutter plotter with many tools for your choice.

A wide range of knife cutting tools for your option such as POT, EOT, creasing wheel, v-cutter, driven tool, wheel knife blade tool, kiss cut tool, drawing tool, hole punching tool, Italy 1100w air cooling router spindle, auto feeding conveyor belt system, CCD camera vision system, Projector nesting system.

As you are thinking of buying a digital knife cutting machine, you should consider how you will operate it.

You can successfully operate the machine only if you understand how the digital plotter cutter machine works. Here is a step-by-step guide on how the digital knife cutter plotter machine works.

Step 1. Design and Draw Processing File

Normally our customer draw the file by the software like illustrator / Coreldraw / Autocad / Solidwork, then export the file as vector format like ***.plt / ***.ai / ***.dxf.

Step 2. Import File To Software

The CNC knife cutting machine adopts the Kinco control system. Through the digital knife cutter plotter's software to set the processing method and optimize the cutting path according to the processing requirements of the material, and then download the file to the controller of flatbed knife cutting plotter machine.

Step 3. Setting of Processing Parameters and Blade Depth

By the digital control panel of the CNC knife cutting machine to set well the processing parameters (cutting speed, acceleration speed, knife blade cutting depth, etc.) to command the machine tool to process the parts.

Step 4. Final Processing

The vacuum pump will switch on automatically when you press the [ Start ] button, and the working table will absorb materials tightly. The digital oscillating knife cutter plotter will process the materials according to the drawings to achieve the purpose of automatic processing.

For more operation details about using the CNC knife cutter plotter machine, please reference the Digital Flatbed Oscillating Knife Cutter Plotter User Manual.

In order to manufacture the best quality digital plotter, all the components are adopted from world-famous suppliers to ensure the knife cutting machine processing accuracy and stable working performance.

1. Advanced Kinco CNC control system with Ethernet port, LED touch screen,easy operation, and powerful.

2. All the wires and drag chains of the plotter cutter machine adopt German Igus, shielded protection, flexible and long-lasting, there is no interference during signal transmission, guarantee the machine is working stable and high accuracy.

3. Flatbed knife cutting machine adopts Japan Yaskawa or Panasonic servo motor and driver, high ratio of torque to inertia, the fast cutting speed with high precision.

4. German Innowelle GmbH reducer for servo motor, excellent positioning accuracy, zero backlashes, high torque capacity.

5. Taiwan guide rail for the transmission system, higher loading capacity, and rigidity achieve a long life with high speed, high accuracy, and repeated positioning precision.

6. France Schneider electric components for our digital knife cutter plotter machine-like circuit breakers, switches, power supply, relays.

7. Taiwan Airtac valve and seal components for air control circuit system, good tightness, and sensitive reaction ensure the stability and working life of the machine.

8. Japan Omron photoelectric sensors, high repeat positioning accuracy, good reliability, long service time, guarantee the machine runs steadily.

9. Whole CNC oscillating knife cut machine is welded with thick 4mm and 6mm square tube structure and treated with high temperature, ensures high accuracy, no deformation, and super long service life. The total weight of the digital knife cutter plotter is about 1450KGS.

10. The anti-collision and emergency stop devices ensure the security of the CNC oscillating knife cutter.

11. Our standard model knife cutter machine's table with eight independently controlled vacuum zones. Each zone can be controlled by the panel, powerful adsorption force for small size materials.

12. Digital knife cutting machine can be equipped multi-function holder with different processing tools to meet various needs.

13. The machine cuts by a knife blade and cutting speed up to 2000mm/s, highly improving production efficiency.

A good quality digital knife cutter plotter machine can highly improve the cutting speed, processing accuracy, and production efficiency. Using the digital knife plotter cutter machine, you will experience a lot of benefits.

► Machine process the materials with the blade; there is no smoke or dust during working. Absolutely environmental protection, no pollution, and good to the staff healthy.

►Digital plotter parts adopt world-renowned suppliers, and the processing precision is increased, thereby enhancing the competitiveness of the products.

► The digital knife cutting machine is highly automated, and you will not require the services of too much human labor and save the cost.

► A high level of automation and advanced quality increase production efficiency to expand the company's output value and business.

► All machine parameters can be monitored and adjusted only from the control surface.

► An intelligent knife cutting machine guarantees your safety since it has photoelectric sensors that automatically shut it down in case of a problem.

► There is an abundant supply of processing tools for processing a variety of materials.

► Simple for maintenance and repair with fast and convenient after-sale service and timely supply of spears.

Different industries with different materials and processing technology, so that the selection of the cutting tool will be various also for our digital knife cutting machine. In order to meet the processing requirements for different materials, we equip our multi-function CNC knife cutter plotter with more than 15 types of tools.

Based on the historical experience of digital knife cutting technology, some suggestions about how to choose the right processing tool are represented for reference:

| Tools/Materials | EOT Tool | POT Tool | Driven Rotary Tool | Universal Cutting Tool | Kiss-cut Tool | Creasing Wheel | V-Cutter | Milling Spindle |

| Leather | √ | √ | √ | |||||

| Fabric | √ | √ | ||||||

| PU | √ | √ | √ | |||||

| Textile | √ | |||||||

| Vinyl | √ | √ | √ | |||||

| Fur | √ | √ | ||||||

| Canvas | √ | √ | ||||||

| Nylon cloth | √ | |||||||

| Cardboard | √ | √ | √ | √ | ||||

| Carton board | √ | √ | √ | √ | ||||

| Gray board | √ | √ | √ | |||||

| Paper | √ | √ | √ | |||||

| Corrugated board | √ | √ | √ | √ | ||||

| Honeycomb board | √ | √ | √ | √ | ||||

| KT board | √ | √ | √ | |||||

| PVC board | √ | √ | √ | |||||

| Adhesive film | √ | √ | √ | |||||

| Sticker | √ | √ | √ | |||||

| Reflective material | √ | √ | √ | |||||

| Wood | √ | |||||||

| Acrylic | √ | |||||||

| Aluminium | √ | |||||||

| MDF board | √ | √ | ||||||

| Foam | √ | √ | ||||||

| EVA | √ | √ | ||||||

| Sponge | √ | |||||||

| Fabric panel | √ | √ | √ | |||||

| Acoustic panel | √ | √ | √ | |||||

| Sound adsorbing cotton material | √ | √ | √ | |||||

| EPE foam | √ | √ | ||||||

| Carpet | √ | √ | ||||||

| Mat | √ | √ | √ | |||||

| Rubber | √ | √ | ||||||

| Fiberglass | √ | |||||||

| Carbon fiber | √ | |||||||

| Ceramic mat | √ | |||||||

| Expansion mat | √ | |||||||

| Gasket | √ | √ | ||||||

| Non-asbestos | √ | √ | ||||||

| PTFE | √ | √ | ||||||

| Tanged graphic | √ | |||||||

| Cork | √ | √ | ||||||

| Teflon | √ | √ | ||||||

| Printed PVC board | √ | √ | √ | |||||

| Printed acrylic | √ | |||||||

| Plastic | √ |

For more materials, processing Video Library is also available for viewing on our YouTube Channel.

For more materials, processing Video Library is also available for viewing on our YouTube Channel.

• EOT tool

• Draw tool

• POT too

• EOT tool

• Draw tool

• Italy 1.1kw spindle

• EOT tool

• CCD camera

• V-cutter tool

• EOT tool

• Draw tool

• V-cutter tool

• Driven rotary tool

• EOT tool

• CCD camera

• Japan NSK spindle

• EOT tool

• CCD camera

• Creasing wheel

• Italy 1.1kw spindle

• EOT tool

• CCD camera

• Creasing wheel

• Hole punching tool

• EOT tool

• Draw tool

• Creasing wheel

• Wheel knife tool

• Japan NSK spindle

• POT tool

• CCD camera

• Creasing wheel

• Projector

• EOT tool

• CCD camera

• Driven rotary tool

• Japan NSK spindle

• POT tool

• CCD camera

• V-cutter tool

• EOT tool

• Draw tool

• Creasing wheel

• Italy 1.1kw spindle

DECKEL CNC with more than ten years of experience for CNC oscillating knife cutting machine, different industries with different materials and processing technology. Please tell us your material and cutting request; we will make a suitable solution for you. You can get more Oscillating Knife Cutting Solutions from DEKCEL CNC.

Home | About Us | Application | Industry News | FAQ | Cnc Hot Products