Brand of DEKCEL, CNC router, CNC laser, CNC parts manufacturers and suppliers in china. Supply different types of cnc routers machine used in different industries.

Views: 29 Author: Site Editor Publish Time: 2017-08-16 Origin: Site

Detailed introduction of cnc co2 laser cutting and engraving machine

Summary

Co2 laser machine can be divided into co2 laser engraving machine and co2 laser cutting machine, which includes the laser power of 40w, 60w, 80w, 100w, 130w, 150w, 260w. In addition, the bigger the laser power is, the bigger the focus spot will be. Therefore, for the BMP processing, if users want to get a good effect when it comes to the wood, marble, glass, acrylic etc, the 80w or the laser power below 80w should be chosen. For the big laser power like 100w, 130w, 150w, 260w, they are mainly used for cutting work. For engraving work, Dekcel don't recommend to use it for a long time. Of course, they can be used for engraving work, but the line will not be fine enough because of the big focus spot.

Co2 laser machine configurations:

1.Laser bed and sheet metal

2.Laser control system

3.Optical system

4.Laser system

5.Water cooling system( water pump or water chiller)

6.Blowing system( air pump or air compressor)

7.Working table of co2 laser cutting machine(blade table or honey nest table)

8.Exhaust system

9.Transmission system

10.Exported free-fumigation plywood case package

11.The supplying parts together with co2 laser machine

Detailed introduction

1.the working table and sheet metal

Customers could choose the type and size we offer, or our company could customize the machine according to the customer requirements, like shape, color, design etc.

1.1 Normally, for the standard size of 6040, 9060, 1390, 1325, company will have them in stock.

Generally speaking, the delivery time is 10-15 working days.

1.2 In special cases, customer could provide machine pictures. Company could customize the machine on the base of the shape, color, designs etc. The delivery time is generally 20-25 working days.

1.3 when it comes to abnormal type machine, such as super large size cnc laser machine, the delivery time about 1 month.

2.cnc co2 laser machine control system

Co2 laser engraving machine control system is composed of PC computer, laser control software, control board and data line. The specific processes are as follow:

2.1 software installation:

The technicians will test the control software to ensure the good operation and store all the operation and control data parameters before shipping. We will copy the control software into U disk and CD and send it together to customer with the machine. After receiving the cnc co2 laser engraving machine, customer could copy the software installation package inside the U disk or CD, open it and install it in the computer.

Open the software, then input the file required, setting the parameters like processing speed, laser power etc and then download the file into control board. At this time, users are expected to put the processing material in the right position and start to work.

2.2 The software format recognized by co2 laser laser control system

2.21 for【imported】 file

Co2 laser machine could import vector and bitmaps. The common vector formats are PLT, DXF, AI etc. The common BMP format are BMP, JPG.

Vector software: CorelDRAW, AutoCAD, illustrator,Solidworks ect.

BMP software: Photoshop

2.22 for【open】file

Co2 laser cutting engraving machine can only open the file stored by its own software. we need to set the relative parameters like processing speed, processing rate, priority typing etc. And then store it into the computer. If users want to process the same file, they don’t need to type again and set the processing speed and laser power rate again, what they need to do is opening the stored file by software. Then put the material right in the position and start to work directly.

2.3 control system

Normal co2 laser cutting and engraving machines like DEK-9060, DEK-1390, DEK-1325 etc adopt RD-C6442D control system.

DEK-1390, DEK-1325 150W/260W co2 laser cutting and engraving machine for metal and nonmetal use RD-6332M control system.

2.4 cnc co2 laser cutting and engraving machine control order’s execution ( take Ruida as example)

2.41 online control

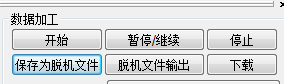

Under the condition of online control, the computer control software and cnc co2 laser machine are connected by a data cable. First of all, users need to make sure the computer and laser machine are connected by data cable, then open the control system, importing the processing file, setting the processing parameters, and then click the【download】button on the right bottom corner of the control system. The processing data will be transmitted into the control board by data cable, what users need to do is putting the material right in the position, adjusting a right processing and then clicking the【 start 】button.

2.42 offline U disk control system

If customers need to transmit data to multi cnc co2 laser cutting and engraving machines, in order to save cost, there is no need to equip the computer to every machine. Users could choose offline control system. The specific operation procedures are as follows: (under this situation, users don’t need to use the data cable to connect the computer and laser machine.

Opening control software-importing the processing patterns-setting processing speed and laser power- saved as offline file- copying the offline file into U disk- put the U disk into USB connection hole- opening the processing file in U disk by control panel- putting the material in the right position- adjusting the focus position- starting to work

3. Optical system

Co2 laser cutting and engraving machine optical system is composed of three reflective mirrors and one focus lens.

Cnc co2 laser machine’s reflective mirrors can be divided into two types: metal Mo and nonmetal Si. The Mo mirror is polished by molybdenum based material which is durable and has good wipr resistance. The silicon mirror is made of silicon based material and has a high reflectivity, which is suitable for high power cutting machine.

Type specifications:

Mirror thickness: 3mm

Mirror diameter: 25mm or 30mm ( the reflective mirror with diameter of 30mm is most commonly used)

Focus lens is made of Znse. For the normal type cnc laser machine, we usually use the focus lens of diameter 20mm, focus length 50.8 or 63.5/

3.1 Mirror maintenance

In order to guarantee the processing effect and efficiency, we recommend to check the cleanliness of three reflective mirrors and focus lens before ever time starting to work. If the mirrors are dirty, the alcohol of more then 90% concentration should be used with cotton stick to wipe the dirty things. When the dirty things are off, adjusting the focus length and start to process.

3.2 The faults of the weak laser power

* check if the focus lens is right or not

*check if the reflective mirrors and focus lens are dirty or not

*attach the dual adhesive tape with laser head. Then hit four points on the upper left corner, the lower left corner, the lower right corner and the upper right corner. Check whether the four points coincide or not. If not coincide, adjust the light path again.

*check if the working blade knifes are at the same height by using the depth gauges.

*check if the working voltage is stable or not

*check if the laser power supply working normally or not.

*make sure the service life of co2 laser tube

4. laser system

Co2 laser cutting and engraving machine laser system is made of laser tube and laser power supply.

4.1 co2 laser tube’s brand is Beijing RECI, Jilin Yongli, Chengdu Weiju etc, which are quite famous.

4.2 There are three lays of laser tube. Co2 gas is in the inner layer, and the outermost layer is of

vacuum condition. And the cooling water flows circularly in the second layer to cool down.

4.3 for laser power, we usually use laser power supply which comes with the brand RECI or Hong

yuanmingyu laser power supply is another choice.

Th installation attention for laser tube

* there are high voltage end and low voltage end. The lo-w voltage end emits laser and it needs

to be near by the the first reflective mirror, the distance is 8-10cm.

* laser tube needs to be cool down to ensure the normal work of it. There are inlet and outlet on

the laser tube. The inlet is downwards and the outlet is upwards when it comes to the installation. Only in this way, the bubble inside the tube could be emit outside to ensure the cooling effect.

* for power supply, high voltage cable is for high voltage end and low voltage cable for low

voltage end. Be sure to buckle the high voltage insulating cap and ensure the machining safety.

5.laser cooling system

Normally, for small laser power 80w or below, the water pump could be used. For co2 laser

cutting machine of big laser power need to be cooled down by water chiller. Water chiller

includes CW 300, CW 5000, CW 5200.

Water pump: be sure the inlet pipe and outlet pipe have a well connection with the machine and put it in the bucket.

Water chiller: we recommend to use purified water to avoid the impurity.

Attention:

* water pump cooling: users would better to use the airtight bucket to avoid dust in the air and make sure the water inside is clean. Users are expected to change clean water if the water quality is of impurity with dust.

* for water chiller, it has good tightness. Purified water should be changed every 5-7days.

6. laser blowing system

Blowing system uses air pump and air compressor

The blowing system,which is seen as protection air, is needed when the co2 laser machine is cutting or engraving. The specific effects are as follows:

* able to ensure the processing effect. For example, for acrylic, users could get a smooth and light surface. For wood, blowing the air could avoid being burned.

* The blowing system could avoid the fume and dust from being stuck on the surface of focus lens. Otherwise, a dirty focus lens will effect the power outlet of focus lens and service life.

Attentions:

* the protective gas used for laser cutting process should be clean, dry, oil-free, and waterless

* for small amount of air supply, air pump is the proper choice

* for big air blow, air compressor will be needed. The output pressure is about 0.8Mpa. As the air itself contains oil and water, we should install the oil-water filter device to purify the gas when using the air compressor to ensure the gas is drying, oil-free and anhydrous.

7.Working table

For working table, there are blade table, honey nest table and up and sown table and double working table.

Blade table: suitable for hard materials, such as wood, acrylic, MDF, plywood and so on.

Honey nest table: for softer materials like cloth, leather, paper, etc.

Up and down table: the processing materials is of large scale, which can not be placed on the working table. So the up and down working table will be needed, which is optional. If the machine is equipped with a rotary device, the up and down table must be used.

8.Exhausting system

It contains fan and air pipe. For countries with high requirements for environment, fume extractor should be equipped with.

9.drive system

The normal type cnc co2 laser machine adopts stepper motor and stepper driver.

When it comes to high precision and high speed cutting or engraving, servo motor and servo driver are a better choice. Taiwan Hiwin rail or TBI screw drive.

Stepper motor: Shenzhen leadshine

Servo motor: Japan Panasonic or Japan Yaskawa

10. package

Adopt international export free-fumigation packing box.

11. Supplied parts together with machine

Common problems

1.software installation

When the machine is shipped, the worker will copy the software installation package that has been tested into the disk or U disk and send i with the machine. When the customer receives the machine, he only needs to copy the software installation package into the computer and install the machine control software.

2.components connection of the laser machine

* take out the laser tube, installing and fixing it, and connect the high pressure end and low pressure end of the laser tube. Then connect the machine and water pump and water chiller by the silica gel water pipe to cool the laser tube.

* connect the water cooler, the air pump and the blower testing machine (note: the water should be circular inside the laser tube before officially starting to work)

3. daily maintenance

* every time before starting to work, users are expected to check the cleanliness of three reflective mirrors and focus lens to ensure the processing effect. For wiping process, the alcohol of more than 90% concentration.

* check the cleanliness of the cooling water of the laser tube

For water pump cooling, users need to pay attention to ensure the cooling water is clean and there is no dust deposition on the bottom of the bucket. If dirty, pls change the water timely.

For water chiller, pure water is recommended. Replace the cooling water once a week.

4.Add oil on the rail once a week

5. clean the dust on the transmission belt to ensure cutting and engraving accuracy.

Hope this article will help you. Jinan Dekcel Cnc Equipment Co., Ltd wil always be at your service.

Home | About Us | Application | Industry News | FAQ | Cnc Hot Products